Custom Dog Food Bags with Slider Zip

Category: Slider Zipper Bag

-

+86 15994887908 WhatsApp

-

linda@hszxpacking.com Email

Custom dog food bags refer to flexible packaging bags specifically manufactured for the pet food industry. These bags utilize composite plastic films as the core material, employing a multi-layered structure to provide excellent protection for dog food kibble, freeze-dried foods, or functional pet foods. Compared to generic packaging, Custom Dog Food Bags emphasize a high degree of customization in size, structure, printing patterns, and opening mechanisms, precisely matching the product positioning and sales scenarios of different brands. In the pet food market, dog food requires high protection against moisture, oxidation, and odor diffusion. Custom dog food bags typically use PET, NY, PE, or aluminum foil composite structures to enhance barrier properties and packaging stability. Through customized zipper, slider closure, or easy-tear designs, the packaging maintains a good seal after repeated opening, helping to extend the freshness of the dog food. Custom Dog Food Bags are not only a means of storage and transportation but also a crucial component of brand presentation, playing a key role in shelf display, e-commerce presentation, and cross-border sales.

Custom Dog Food Bags with Slider Zip Specifications

| Zipper Material | PE |

| Bag Material | PET/PE or PET/NY/PE or PET/NY/White PE or PET/VMPET/PE, OPP/VMPET/PE, etc. |

| Place of Origin | Guangdong, China |

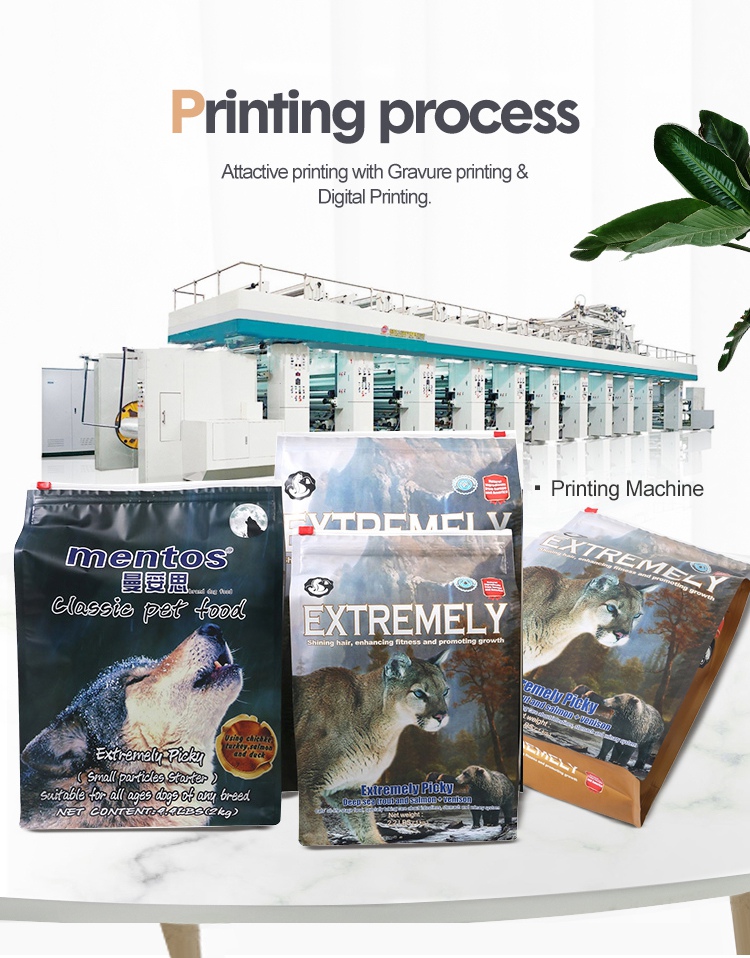

| Printing Way | Gravure and Digital |

| Application | Food and daily necessities |

| Feature | Air and Moisture Proof |

| OEM/ODM | Availalbe |

| Colors | Up to 10 colors |

| Terms of Trade | FOB, CIF |

| Sample | Free sample |

| Lead Time | About 10 to 25 days |

| MOQ | 100pcs by digital; and 10000pcs by gravure |

| Bag Type | Support all kinds of style such as SUP, Flat Bottom, etc. |

| Material Structure | Plastic Laminated, such as PET/PE, PET/VMPET/PE, etc. |

| Transportation | By Air, By Ocean, By Courier |

| Quality/Safety Certification | ISO90012015; BRCS, SGS, FDA |

| Packaging | Carton with PE bag inside, with pallet wrapped |

Custom Dog Food Bags with Slider Zip Product Details

1. Flexible Overall Customization

This product offers a high degree of customization in pattern design, bag structure, and material combination. Brands can choose between stand-up pouches or flat-bottom bags based on product positioning. Packaging capacity covers the common range of 500g to 5kg. The printing area can fully display formula information and brand visuals. The bag proportions can be adjusted according to display needs. The material structure and appearance design are matched to ensure molding stability. Dimensional tolerances are controlled within industry standard ranges during production. Custom Dog Food Bags are designed to meet market demands from the design stage, offering high overall adaptability.

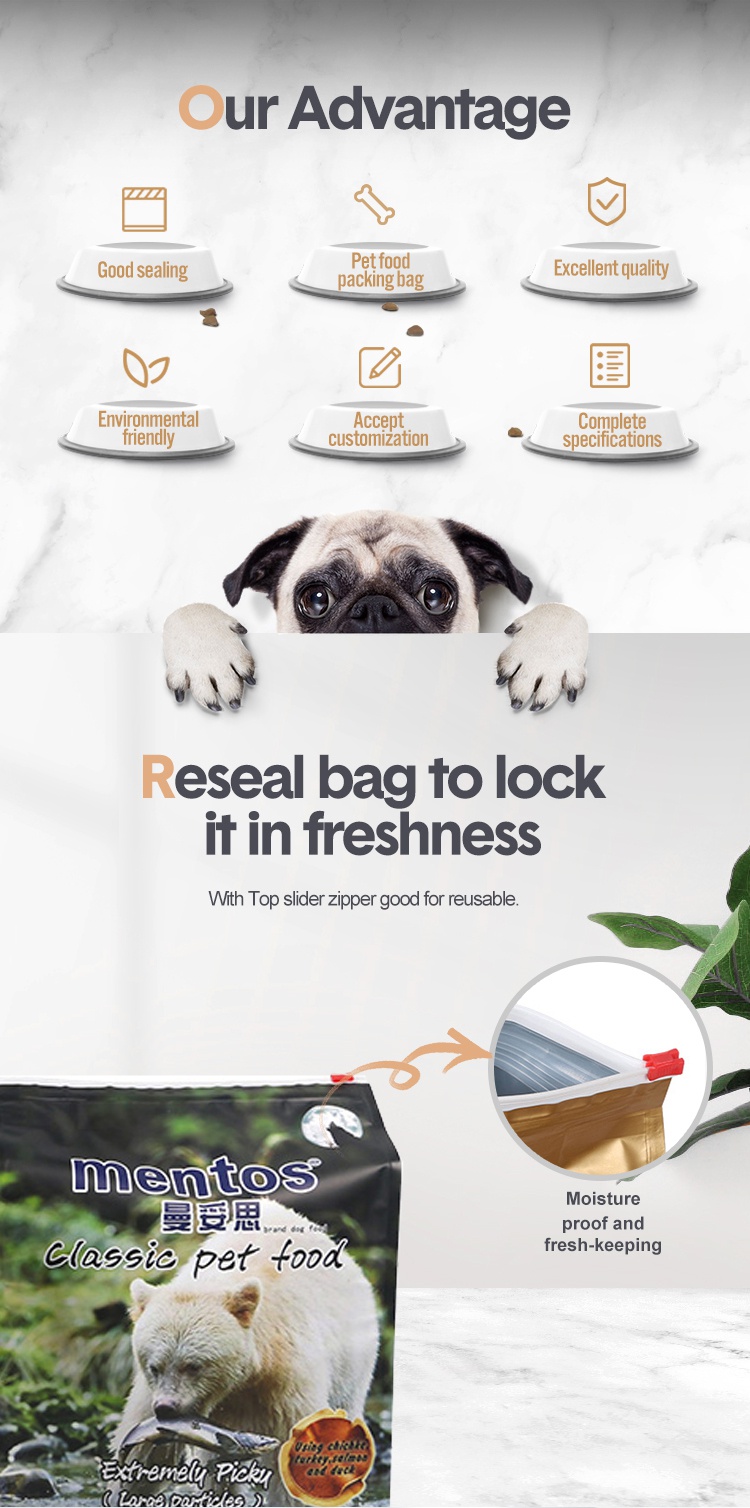

2. Slider Zipper Sealing Structure

The product uses a Slider Zipper design, making the opening and closing process more intuitive. The slider runs smoothly in the track, reducing the likelihood of zipper misalignment. Common zipper widths are 8mm or 10mm, suitable for medium to large dog food packaging. The zipper material is highly compatible with the bag body and is less prone to hardening. It maintains sealing performance even after repeated opening. Consumers can operate it with less effort. Custom Dog Food Bags enhance the daily user experience with this structure. The packaging is more practical for everyday use.

3. Multiple Composite Material Options

Bag body materials can be selected from structures such as PET/PE, PET/NY/PE, PET/NY/White PE, PET/VMPET/PE, or OPP/VMPET/PE. Different material combinations have varying emphasis on barrier properties. Common total thickness is controlled between 90μm and 130μm. The NY layer helps enhance puncture resistance. The VMPET layer reduces water vapor transmission rate. The materials meet standard food packaging requirements. Custom Dog Food Bags offer flexible material options to suit various types of dog food.

4. Stable Preservation Performance

The multi-layer composite structure, combined with the slider zipper, helps reduce air entry into the packaging. The sealing area is flat, which helps maintain sealing strength. The heat seal strength meets common industry standards. The bag's moisture barrier properties are suitable for room temperature storage environments. The packaging is less prone to leakage during transportation and stacking. The internal environment is more conducive to maintaining the original state of the dog food. Custom Dog Food Bags demonstrate stable performance in sealing and preservation. Overall safety is easier to control.

5. Balancing Display and Practicality

The bag surface can be chosen with a glossy or matte finish to enhance visual appeal. The white PE or aluminum-laminated structure helps improve printing clarity. The self-standing structure ensures the packaging stands upright well on the shelf. The bag features clean lines and a more organized overall appearance. The material's rigidity supports stable packaging form. The information area is clearly laid out for easy reading. Custom Dog Food Bags strike a balance between display effectiveness and practicality, making them ideal for retail sales.

Custom Dog Food Bags with Slider Zip Application

1. Pet Food Retail Stores

In pet food retail stores, Custom Dog Food Bags facilitate neat and organized display. The self-standing structure keeps the packaging stable on shelves. Clear front-panel information helps consumers quickly identify the product. The slider zipper makes it easier for customers to understand how to use it. Multiple size options support different consumer needs. The overall packaging is better suited to the offline sales environment.

2. Pet Brand E-commerce Warehousing

In e-commerce warehousing, packaging needs to be highly durable. Custom Dog Food Bags maintain their integrity during stacking and sorting. The composite material structure reduces the risk of damage from transportation friction. The zipper seal reduces powder spillage. Uniform specifications facilitate inventory management. Overall, it helps improve shipping stability.

3. Pet Food Manufacturing Plants

In manufacturing plants, packaging needs to be compatible with filling and sealing processes. Custom Dog Food Bags can be customized with bag opening sizes according to equipment requirements. The heat-sealed area of the bag is flat, facilitating stable sealing. The material's temperature resistance meets conventional processing conditions. The bag strength is suitable for continuous production operations. This helps improve production efficiency.

4. Overseas Wholesale and Distribution Centers

In wholesale and distribution warehousing, packaging undergoes multiple handling processes. Custom Dog Food Bags have good compression resistance and wear resistance. The multi-layer material structure helps cope with changes in environmental humidity. The bag's appearance remains clean throughout the storage period. Clear labeling facilitates zone management. Suitable for longer logistics processes.

5. Pet Supplies Chain Stores

In chain store sales channels, packaging consistency is very important. Custom Dog Food Bags support long-term bulk customization. Specifications and appearance remain stable, facilitating unified channel management. The slider zipper enhances the end-user experience. The material structure meets the needs of high-turnover sales. More suitable for large-scale distribution scenarios.

Additional Features

Our company offers a variety of value-added features to enhance the functionality and appeal of our packaging solutions. These include Aplix Velcro Zipper for easy open and reseal, Top Slider Zipper for convenient access, Pocket Zipper for added convenience, Hot Stamping Foil for decorative and branding purposes, Custom Shaped Window to showcase the product inside, Laser Scoring for easy tearing, One Pouch One Product code for traceability, Plastic Handle for easy carrying, and Tin tie for better sealing. These features are designed to meet diverse customer needs and add extra convenience and attractiveness to the packaging.

Experimental Testing

Our company is equipped with a comprehensive range of advanced testing instruments in our laboratory to ensure the quality and safety of our products. These instruments include Gas Chromatography (GC) for chemical analysis, a Coefficient of Friction (C.O.F) Tester to measure surface properties, a Tensile Tester for assessing material strength, a Bar Code Scanner for accurate product identification, a Film Impact Tester to evaluate durability, WVTR & OTR Testers for measuring moisture and oxygen transmission rates, an Electronic Microscope for detailed surface examination, and a Retort Chamber for testing heat resistance. These tools enable us to conduct thorough tests on various aspects of our packaging materials, guaranteeing that they meet the highest standards before they reach our customers.

Packaging Logistics

At Heshan Zhongxing Laminated Packing Co., Ltd., we pay great attention to both packaging and transportation to ensure the safety and integrity of our products during transit. In terms of packaging, we use sturdy cartons with a protective PE bag inside to safeguard our products. Additionally, we employ pallet wrapping to further secure the goods, preventing any damage during handling and shipping. As for transportation, we offer flexible options to meet different customer needs. We can ship by air for urgent orders that require quick delivery. For larger quantities or when time is less of a constraint, we utilize ocean freight, which is cost - effective and reliable. We also provide courier services for smaller shipments that need to be delivered promptly and directly. Our comprehensive packaging and transportation solutions are designed to ensure that our products reach our customers in perfect condition, no matter the distance.

Exhibition Information

Heshan Zhongxing Laminated Packing Co., Ltd. is an active participant in various industry exhibitions. We see these events as excellent opportunities to showcase our extensive range of high - quality plastic flexible packaging products, such as SUP, Kraft Paper Pouch, Spout Pouch, and more. By attending these shows, we can directly interact with clients from around the world, understand their needs better, and demonstrate our capabilities in providing customized packaging solutions. Our experienced team is always ready to answer questions and discuss potential collaborations at these exhibitions, further strengthening our position in the global packaging market and expanding our business network.

Cooperative Customers

Our company has established strong partnerships with renowned global brands such as NISSIN, Woolworths, PHILIPS, and Nestlé. These collaborations reflect our commitment to delivering high - quality packaging solutions that meet the stringent standards of industry leaders. Working with these esteemed partners has not only enhanced our capabilities but also reinforced our reputation for reliability and innovation in the packaging sector.

Heshan Zhongxing Laminated Packing Co., Ltd. located in Heshan, Jiangmen city of Guangdong Province. Established in 1993, we specialized in plastic flexible packaging with more than 30 year’s rich experience. The workshop takes 20000 square meter land area and meet the international standardization and strictly control the hygiene and safety.

Wide ranges include SUP, Kraft Paper Pouch, Spout Pouch, Flat Bottom/Quad Seal Pouch, Recyclable Pouch, Laser Score Pouch, PVC&APET Sheet, Velcro/Slider/Pocket Zipper Pouch, Retortable Vacuum Pouch, Peelable Lidding Roll Film, Hot Foil Stamp Pouch, Coffee Valve Pouch and so on.

4 production lines with big capacity,which equipped with 4 printing machines, 4 automatic inspection machines, 5 lamination machines, 5 slitting machines and 20 bag making machines.

We obtained the ISO9001:2015 and BRC certification, products are passed the SGS Testing Approval. We have our own independent laboratory, from the raw material to finished products, every step is tested strictly to check the qualification of products.

We always insist on “Quality First, Reputation First, Customer First”, Adhering to the business principle of mutual benefits, we have had a good reputation among our customers.

We plan to build a modernization new factory with 9000 square meters in the next 2 years.